Polypropylene (PP) spunbond non-woven fabric plays a vital role in Medical and Hygiene field, by providing a lightweight, breathable, yet highly effective barrier against pathogens and fluids. Its unique structure—continuous filaments thermally bonded into a uniform web—delivers high tensile strength, lint-free performance, and compatibility with sterilization processes such as ethylene oxide, steam, or gamma irradiation.

1. Face masks

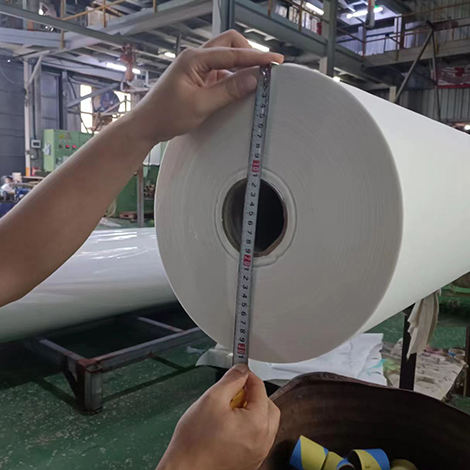

• Inside and Outer layers (if 3ply mask then 1st and 3rd layer): normally use 25 g/m² PP spunbond fabric, width 19.5cm and 17.5cm. Roll length 2000meter reduce production swift time. This nonwoven offers splash resistance and mechanical strength, resisting tearing during donning and extended wear.

2. Head covers (bouffant caps and surgical hoods)

• Elastic edge integration: The fabric’s uniform elongation allows secure fit without hair protrusion, maintaining aseptic fields. 10-20gsm is suitable for this application.

• Anti-static version: Added antistatic masterbatch into production line, will effectively reduce the generation of static electricity. This may be required in some operating rooms where electronic equipment is operated. A similar example is the shoe covers used in computer rooms and factories where electronic equipment is widespread.

3. Medical curtains

• 60–120 g/m² weight provides opacity for patient privacy while remaining light enough to glide on ceiling tracks.

• Anti-bacterial version: Silver-ion or PHMB coatings inhibit bacterial growth on cubicle curtains, lowering nosocomial infection rates.

E-mail : marketing@henghuanonwoven.com

Add : No.260 Liqi Road Hangcheng Street, Changle District, Fuzhou City, Fujian Province, China

leave a message

Scan to Wechat :

Scan to WhatsApp :