Application of Nonwovens

Polypropylene spun-bond non-woven is quietly revolutionising home textiles at a fraction of the weight, bulk and cost. 1. Pillow covers & protectors • 30–60 g/m² spun-bond is ultrasonically welded or sewn into zippered envelope covers that slip over feather or memory-foam pillows. • Hydrophobic yet breathable, it blocks dust-mites, saliva and perspiration while allowing air to circulate, extending pillow life. 2. Garment & suit bags • 50–120 g/m² fabric is die-cut and side-sealed to create lightweight suit/clothes protect cover. • High tear strength (≥60 N/5 cm) prevents snagging on hangers or zips; • Anti-static verstion: antistatic processed nonwoven able to eliminates cling and lint pick-up. 3. Dust covers & seasonal storage • 70–100 g/m² heavy-weight grades are used for sofa, mattress and luggage covers. • UV-resistant treated maintain colour after months of attic or garage storage; breathable construction prevents musty odours and mildew. • Draw-cord or elastic hems can be ultrasonically tacked in-line, eliminating stitching and reducing labour by 35 %. 4. Decorative & functional layers • Low-grammage versions (12–25 g/m²) act as internal quilting backings or interlinings in comforters, bed skirts and headboards, adding loft without bulk. From the unseen pillow protector to the printed suit bag hanging in a hotel wardrobe, PP spun-bond non-woven brings hygiene, protection and style to everyday home textiles—at a lower environmental footprint than traditional woven solutions. Pillow cover Garment Protect Bag Dust Cover -

Explore More

In the furniture industry, PP spunbond non-woven fabric is widely used as: Upholstery Lining: It serves as a durable inner lining for sofas, chairs, and mattresses. This lining provides a smooth, protective layer that prevents filling materials from shifting or protruding while extending the furniture's lifespan. Mattress Components: The fabric is used for spring pocket encasement, bottom covers, and as a protective layer beneath the mattress ticking. Its high tensile strength ensures structural integrity, while its breathability helps prevent mold and mildew. Protective Covers: Due to its tear resistance and lightweight nature, it is ideal for temporary protective covers for furniture during transportation, storage, or renovation. Spring pocket Mattress/Sofa/Chair lining Upholstery Lining

Explore More

Polypropylene (PP) spunbond non-woven is rapidly becoming the backbone of modern, sustainable packaging. Its high tensile strength, light weight, water resistance and inherent recyclability allow it to replace paper, woven jute and virgin plastic in a growing number of applications. Environmental edge • 100 % polypropylene construction means the entire structure is recyclable in the same stream as bottle caps. • Life-cycle studies show a 60–70 % CO₂ reduction versus single-use PE bags after 10 reuse cycles. From supermarket carriers to romantic flower wraps, PP spunbond non-woven delivers packaging that is strong, printable, protective and planet-friendly.

Explore More

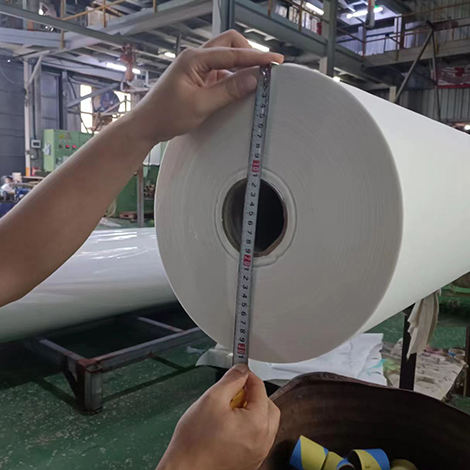

Polypropylene (PP) spunbond non-woven fabric plays a vital role in Medical and Hygiene field, by providing a lightweight, breathable, yet highly effective barrier against pathogens and fluids. Its unique structure—continuous filaments thermally bonded into a uniform web—delivers high tensile strength, lint-free performance, and compatibility with sterilization processes such as ethylene oxide, steam, or gamma irradiation. 1. Face masks • Inside and Outer layers (if 3ply mask then 1st and 3rd layer): normally use 25 g/m² PP spunbond fabric, width 19.5cm and 17.5cm. Roll length 2000meter reduce production swift time. This nonwoven offers splash resistance and mechanical strength, resisting tearing during donning and extended wear. 2. Head covers (bouffant caps and surgical hoods) • Elastic edge integration: The fabric’s uniform elongation allows secure fit without hair protrusion, maintaining aseptic fields. 10-20gsm is suitable for this application. • Anti-static version: Added antistatic masterbatch into production line, will effectively reduce the generation of static electricity. This may be required in some operating rooms where electronic equipment is operated. A similar example is the shoe covers used in computer rooms and factories where electronic equipment is widespread. 3. Medical curtains • 60–120 g/m² weight provides opacity for patient privacy while remaining light enough to glide on ceiling tracks. • Anti-bacterial version: Silver-ion or PHMB coatings inhibit bacterial growth on cubicle curtains, lowering nosocomial infection rates. Face Mask Hospital Bed Sheet Coverall Head Cover Medical Curtain

Explore More

Construction dust-proof cover, slope protection, slope/urban/enginer greening Polypropylene spunbonded nonwovens are degradable and environmentally friendly materials. Ultra-thin weight, such as 10-20gsm, can be used in dust-proof soil covering, slope protection and greening, urban greening, engineering greening and other fields. Besides this kind of non-woven fabric, there are other non-woven fabrics used in these fields, depending on the project budget and local regulations. It can stop weeds and let air and water reach the roots of plants at the same time. The additives stabilized by ultraviolet light can keep the outdoor service life of the fabric for 3-5 months before natural fragmentation, protect the fragile period of plant production, and reduce the use of herbicides and disturb the soil. Camping tablecloth • 50–60 g/m² sheets are heat-cut to picnic-table size and edge-sealed to prevent fraying. • Hydrophobic surface repels spills, wipes clean and dries in minutes. • Soft, noise-free texture won’t scratch cookware, and the fabric folds to pocket-size for backpackers. Whether protecting garden beds or serving as a lightweight picnic surface, single-layer PP spun-bond delivers durable, recyclable performance for greener living and hassle-free outdoor fun.

Explore More

PP Spunbond non-woven is widely used as cover material, interlining material in luggage product and footwear because it delivers high tensile strength, uniform thickness and excellent mouldability at minimal weight and cost. Luggage box/case Cover or Interlining material • Shell reinforcement: 80–150 g/m² spun-bond sheets are heat-laminated to the outer fabric or hard-shell ABS/PC panels, preventing surface dents and improving impact resistance without adding bulk. • Pocket & divider stiffeners: die-cut pieces are sewn or ultrasonically welded inside compartments to keep documents and electronics flat; the material’s puncture resistance stops pen points or keys from piercing through. Shoe interlining • 10–150 g/m² wide range are used as shoe interlining.Most client of us require Dot pattern, also some client require Cross pattern. As shoe interlining, our spun-bond fabric used as heat-pressed between the outer leather or mesh and the lining, creating a lightweight yet rigid support that maintains shoe shape and prevents creasing . • Insole board: 120–180 g/m² high-density grades replace traditional Texon boards; the non-woven absorbs minimal moisture, reducing odour and improving long-term flex life. • Counter & heel backing: fabric coated with low-melt adhesive is easily activated at 120 °C, bonding instantly to PU or rubber counters during vulcanisation while maintaining breathability.

Explore More

Polypropylene (PP) spunbond non-wovens are widely adopted in the automotive sector thanks to their high strength-to-weight ratio, moldability and cost efficiency. 1. Interior trim backing • 60–120 g/m² fabric is thermally laminated to PVC, TPO or foam to form door-panel inserts, seat-back boards and parcel shelves, adding rigidity while keeping overall part weight low . 2. Headliner substrate • A single ply of 80–150 g/m² spunbond acts as the core scrim between foam and decorative fabric, providing dimensional stability and sound absorption without sagging in high-temperature cockpits . 3. Insulation & acoustic wraps • 50–100 g/m² layers are wrapped around wiring harnesses or HVAC ducts to dampen vibration and prevent chafing; the hydrophobic nature repels moisture, avoiding corrosion. 4. Maintenance site/4S-Shop Seat Protector • 30–50 g/m² white or blue spunbond is die-cut and elastic-banded into universal-fit seat covers. • Hydrophobic yet breathable, it blocks grease, dust and sweat from workshop clothes, keeping leather or fabric upholstery spotless during service. • Quick-on / quick-off design cuts technician time and is 100 % recyclable, meeting dealership green-waste protocols. 5. High-Speed Rail & Aircraft Headrest Covers • 25–35 g/m² spunbond is pre-formed into stretchable “slip-over” sleeves that hug headrest contours without shifting. • Single-use barrier prevents hair-oil, make-up and dandruff transfer between passengers, satisfying airline and rail hygiene audits. • Light weight (<2 g per piece) keeps disposal volumes minimal and cabin waste costs low. Car interlining Seat Protect Cover Headrest Cover -

Explore More

Applications of PP spun-bond non-woven in agriculture and horticulture Crop protection: spun-bond covers create a miniature greenhouse that raises soil temperature, shields seedlings from frost, wind, hail, insects and birds, and cuts pesticide use while accelerating harvests . Weed moisture: Anti-UV processed pp spunbond fabric suppresses weeds, reduces evaporation, keeps soil loose and boosts fertiliser retention . Seed Grow management: PP spunbond non-woven fabric made Seed bags could reduce transplant shock, save labor and reduce plastic waste while keeping moisture and breathability. Fruit nursery care: lightweight, anti-UV bags and fruit sleeves prevent sunburn and pest damage, improving grade-out rates.It’s widely used in fruit bananas, grapes etc. The material is recyclable. According to customers’ requirement, we could produce with anti-UV feature or without, hydrophobic or hydrophilic to permeable to water. Natural feature is air breathable and available in 10–250 g/m² density, customized width, making it an eco-friendly, cost-efficient solution for modern farming. Crop Cover Weed moisture Seed grow Fruit nursery care

Explore More

E-mail : marketing@henghuanonwoven.com

Add : No.260 Liqi Road Hangcheng Street, Changle District, Fuzhou City, Fujian Province, China

leave a message

Scan to Wechat :

Scan to WhatsApp :