Meta Description: Discover what spunbond polypropylene (PP) nonwoven fabric is, how it's made, its key properties, and why it's a critical material across industries from medical to agriculture.

If you've ever used a reusable shopping bag, worn a disposable medical gown, or noticed a protective cover over a newly seeded field, you've likely encountered spunbond polypropylene. This versatile engineered fabric is one of the most widely used nonwoven materials in the world. But what exactly is it, and what makes it so special?

This guide breaks down the essentials of spunbond polypropylene (PP) fabric, explaining its manufacturing process, unique characteristics, and the reasons behind its global popularity.

Spunbond polypropylene is a type of nonwoven fabric made from 100% polypropylene polymer. The term "spunbond" refers to the specific manufacturing process where continuous filaments are spun, laid into a web, and then bonded together—without weaving or knitting. The result is a strong, uniform, and porous sheet material that balances performance with cost-effectiveness.

Understanding the production process helps explain the fabric's consistent quality and properties.

Polypropylene resin—in the form of small pellets—is melted and extruded through a die called a spinneret, which contains hundreds of tiny holes. As the molten polymer is forced through these holes, it forms continuous, fine filaments (like endless strands of spider silk).

These still-soft filaments are then stretched (a process called drawing) by high-speed air, which aligns their molecules, increasing their strength. They are then pneumatically laid onto a moving conveyor belt in a random, overlapping pattern, forming a uniform, unbonded web.

The final and critical step is bonding the web to give it integrity. For polypropylene, the primary method is thermobonding. The web passes through heated calendar rollers (often with an embossed point-bond pattern). The heat slightly melts the PP filaments at their交叉点, fusing them together as they cool. This creates a strong but breathable fabric.

The combination of the base material (polypropylene) and the spunbond process results in a unique set of properties:

High Strength-to-Weight Ratio: Despite being lightweight, it offers excellent tensile and tear resistance, especially in the machine direction.

Dimensional Stability: It does not fray or unravel like woven textiles, and it is resistant to stretching and shrinking.

Inherently Inert & Hypoallergenic: Polypropylene is chemically resistant to most acids, alkalis, and solvents. It is also non-toxic and safe for skin contact, making it ideal for hygiene products.

Moisture Resistance: PP is hydrophobic—it does not absorb water. This makes the fabric an excellent moisture barrier and allows it to dry quickly.

Breathable & Porous: The point-bonded structure allows air and vapors to pass through, preventing condensation and increasing comfort in applications like protective covers.

Cost-Effective Manufacturing: The process is fast, continuous, and highly automated, allowing for high-volume production at a low cost per square meter.

Customizable: Its properties can be easily modified. It can be treated to be hydrophilic (water-absorbing), given UV stabilization for outdoor use, or have antimicrobial and anti-static properties added. Weight (GSM), color, and width can all be tailored.

This versatility translates into hundreds of everyday and industrial uses:

Medical & Hygiene: The #1 use. Surgical gowns, drapes, face masks, shoe covers, diaper liner stock, and adult incontinence products.

Geotextiles & Agriculture: Weed control fabric, crop covers, soil stabilization mats, and drainage layers due to its durability and permeability.

Packaging: Reusable tote bags, protective furniture wraps, breathable produce packaging, and mailer envelopes.

Furniture & Bedding: As a backing for carpets and upholstery, and as a protective dust cover in mattresses and furniture.

Filtration: Used as a pre-filter layer in HVAC systems, water filters, and vacuum bags.

Spunbond vs. Meltblown: Meltblown PP creates extremely fine fibers, resulting in superior filtration (used in N95 masks) but is less strong. Often, they are combined to form SMS (Spunbond-Meltblown-Spunbond) fabric, which is strong, breathable, and an excellent barrier—common in medical gowns.

Spunbond vs. Needlepunched: Needlepunched fabrics are mechanically entangled, making them thicker and more felt-like, ideal for insulation or wipes, but generally less smooth and consistent than spunbond.

Spunbond vs. Woven Polypropylene: Woven PP is made from tapes, is heavier, and can have a checkerboard look. It's very strong for bags but is less cost-effective for disposable/lightweight applications and is not a true barrier.

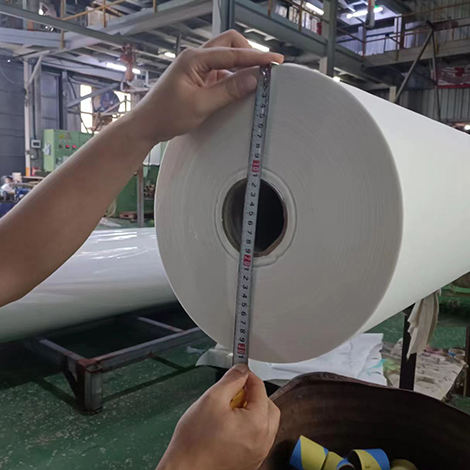

As a manufacturer specializing in spunbond polypropylene, we control the process from resin to roll. This allows us to guarantee consistency, provide technical guidance, and customize fabrics to meet precise application challenges.

At Henghua Nonwoven, we specialize in high-quality polypropylene spunbond nonwoven fabrics tailored to your needs. Whether you require standard or custom weight/width, anti-uv, antistatic,hydrophobic treatment, color matching, or specialized functionalities (antibacterial, flame retardant, etc.), we provide not only nonwoven roll but also technical guidance to help you select between PP, polyester, or other options.

We Ensure:

Looking for a reliable spunbond PP solution??

Contact our team today for a free consultation and sample testing. Let us help you make an informed choice that enhances your product's performance and value.

Email: marketing@henghuanonwoven.com

Website: www.henghuanonwoven.com

E-mail : marketing@henghuanonwoven.com

Add : No.260 Liqi Road Hangcheng Street, Changle District, Fuzhou City, Fujian Province, China

leave a message

Scan to Wechat :

Scan to WhatsApp :