Among numerous industrial materials, there is a material that, although not often mentioned by the public, has silently penetrated into every aspect of our lives. It exists in the wet wipes used in the morning, in the barriers of hospital protective clothing, in the tough texture of supermarket eco-friendly bags, and even covers the surface of farmland to protect crops. This multifunctional material, PP spunbond non-woven fabric, can be called the "invisible skeleton" of modern manufacturing industry.

So, what exactly is PP spunbond non-woven fabric?

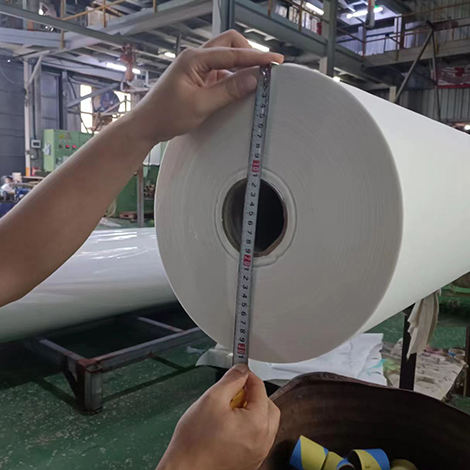

How is it different from traditional textiles and other non-woven fabrics? Simply put, spunbond method is a one-step process in which chemical fiber raw materials (mainly polypropylene PP) are melted at high temperatures, spun, laid, and then directly consolidated into cloth through hot rolling or chemical methods. This efficient process abandons the traditional "spinning+weaving" process and gives the product unique advantages: high strength, good tensile strength, breathability, stable process, and controllable cost. These characteristics make it quickly stand out from numerous non-woven fabric processes such as needle punching, hydroneedling, and meltblown, becoming one of the most widely used categories.

Why can PP spunbond non-woven fabric dominate the market?

Its core competitiveness lies in the perfect balance between performance and cost. Compared to short fiber hydroentangled fabrics with soft texture, spunbond fabrics have a more skeletal feel and are suitable for applications that require shaping; Compared to the meltblown fabric used for the core layer of masks, it provides better basic strength and support. From a thin and lightweight medical mask outer layer to a sturdy geotextile, spunbond fabrics of different weights and post-treatment can handle it. Currently, many leading non-woven fabric manufacturers are committed to improving their functionality, such as developing hydrophilic, anti-static, antibacterial or biodegradable PP spunbond non-woven fabrics, in response to the trend of environmental protection and consumer upgrading.

Looking ahead to the future, the application boundaries of PP spunbond nonwoven fabrics are still expanding.

With the rise of new energy vehicles, their application prospects in battery separators and interior materials are broad; In the field of agriculture, biodegradable long-lasting agricultural fabrics reduce white pollution; Personal care products continue to pursue a more comfortable and safe material experience. This seemingly ordinary material, with its solid quality and continuous innovation, silently supports a cleaner, more efficient, and healthier world. The next time we come into contact with a disposable medical product or a sturdy packaging bag, we may feel that PP spunbond non-woven fabric is playing an indispensable role behind it.

Our company's product recommendations:

E-mail : marketing@henghuanonwoven.com

Add : No.260 Liqi Road Hangcheng Street, Changle District, Fuzhou City, Fujian Province, China

leave a message

Scan to Wechat :

Scan to WhatsApp :