All About Polypropylene Spunbond Non-Woven Fabric: A Comprehensive Guide

Dec 17, 2025

As a leading manufacturer of polypropylene spunbond non-woven fabrics, we often receive questions about this versatile material—its properties, applications, advantages, and considerations. Based on common inquiries and expert insights, let’s explore what makes spunbond non-woven fabric a preferred choice across industries.

What is Spunbond Non-Woven Fabric?

Spunbond non-woven fabric is a type of fabric made from polypropylene polymer. Unlike traditional woven or knitted textiles, it is produced by extruding continuous filaments of polypropylene, which are then laid into a web and bonded together through mechanical, thermal, or chemical processes—often without the use of additional adhesives. The result is a strong, uniform, and porous material with a wide range of uses.

Key Properties of Polypropylene Spunbond

Material Safety & Non-ToxicityA common concern is whether polypropylene spunbond is safe. Rest assured: despite being a synthetic polymer, it is non-toxic and non-dangerous. Our spunbond fabric undergoes mechanical and thermal bonding without harsh chemicals, making it suitable for sensitive applications such as medical, hygiene, and food packaging.

BreathabilitySpunbond is highly breathable, allowing air and moisture vapor to pass through while providing a protective barrier. This makes it ideal for products that require ventilation, such as agricultural covers, hygiene products, and protective apparel.

Strength & DurabilityWhile some non-woven fabrics may have limitations in strength compared to woven textiles, modern spunbond fabrics are engineered for durability. Through advanced manufacturing techniques, we produce fabrics with excellent tensile strength and resistance to tearing, suitable for heavy-duty applications like geotextiles, furniture lining, and industrial packaging.

Water Resistance vs. WaterproofingSpunbond is not inherently waterproof due to its porous structure. However, it can be treated with coatings or laminations to enhance water repellency for specific uses, such as in medical gowns, disposable tablecloths, or construction membranes.

Spunbond vs. Other Non-Woven Fabrics

It’s important to distinguish spunbond from other non-woven types like spunlace, which is softer and more absorbent due to its hydroentanglement process. Spunbond, in contrast, is stronger, more durable, and better suited for structural applications. Other common non-woven types include melt-blown (used in filtration) and heat-bonded fabrics.

Applications of Polypropylene Spunbond

Our fabric is used across diverse sectors:

Medical : Surgical gowns, masks

Agriculture: Crop covers, weed control fabrics, and seedling protection.

Packaging: Shopping bags, protective wrapping, and breathable produce packs.

Home & Industrial: Furniture backing, carpet underlay, insulation, and filters.

Geotextiles: Erosion control, drainage layers, and road stabilization.

Environmental & Health Considerations

Polypropylene spunbond is generally considered safer than many synthetic fabrics. Unlike polyester, acrylic, or nylon—which may involve harmful chemicals—our polypropylene fabric is produced with minimal additives and is recyclable under appropriate systems. We prioritize eco-friendly production methods and offer options for biodegradable or recycled-content spunbond.

Why Choose Our Polypropylene Spunbond?

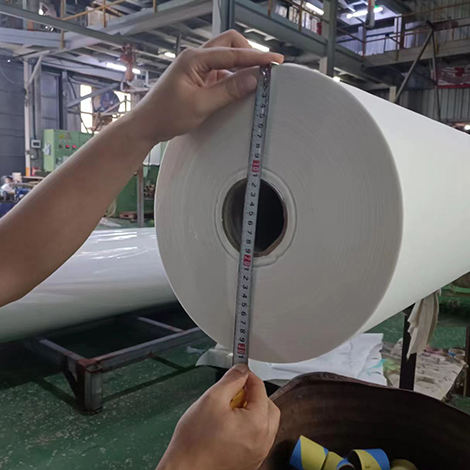

Consistent Quality: Advanced manufacturing ensures uniform weight, strength, and texture.

Customizable: Available in various weights, colors, widths, and with added treatments (hydrophobic, antimicrobial, UV-resistant).

Cost-Effective: Efficient production makes it an affordable alternative to woven fabrics.

Versatile: Adaptable to both disposable and durable product designs.

Conclusion

Polypropylene spunbond non-woven fabric is a reliable, safe, and highly functional material that continues to evolve with technological advancements. Whether you need breathable medical textiles, sturdy geotextiles, or lightweight packaging solutions, our spunbond fabric offers the performance and flexibility to meet your needs.

Interested in learning more or requesting a sample? Contact our team today—we’re here to help you find the perfect non-woven solution for your application.