Versatile Applications and Customized Production Guide for Spunbond Nonwoven Fabric

Dec 04, 2025

Introduction: Understanding the Multifunctionality of Spunbond Nonwoven

Spunbond nonwoven is a type of nonwoven material formed by extruding molten polymer, stretching it into continuous filaments, and then reinforcing it through thermal calendering or chemical bonding. This manufacturing process endows spunbond nonwoven with a unique balance of properties: excellent strength, good breathability, and outstanding uniformity. As a spunbond nonwoven manufacturer certification, we are committed to providing high-quality, multipurpose nonwoven solutions for our clients.

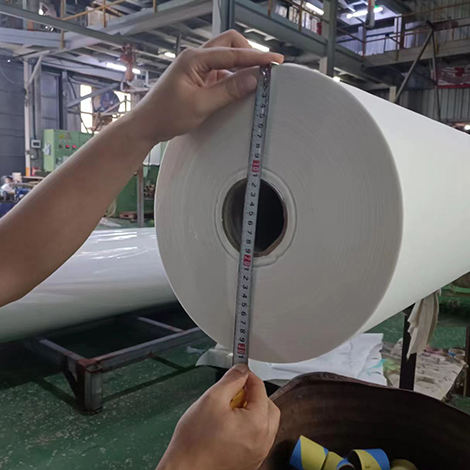

Our Production Capabilities and Technical Specifications

Our factory is equipped with advanced production machinery and a skilled technical team, enabling us to meet diverse requirements across various industries:

Parameter

Specification Range

Description

Weight

10-250 gsm

From ultra-lightweight to heavy-duty, catering to different strength needs

Width

15-255 cm

Flexible dimensions compatible with various processing equipment

Length

Customizable

Supplied in rolls or sheets according to customer requirements

Color

Customizable

Standard white or custom dyeing services available

Characteristics

Customizable

Optional features include antistatic, flame-retardant, hydrophilic/hydrophobic properties

iverse Application Fields of Spunbond Nonwoven

1. Home Furnishings and Interior Decoration

Spunbond nonwoven finds extensive applications in the home sector, including:

Furniture padding: Serving as underlay material for sofas and mattresses, providing support and dust prevention

Wall covering substrate: Offering a smooth base surface for wallpapers and wall fabrics

Curtain lining: Enhancing the drape and light-blocking properties of curtains

Mattress protectors: Water-resistant yet breathable, safeguarding mattresses from stains

2. Agricultural and Horticultural Applications

In agriculture, spunbond nonwoven plays a significant role:

Crop cover fabric: Regulating soil temperature and suppressing weed growth

Insect barrier netting: Physical protection against pest infestation

Greenhouse insulation material: Reducing heat loss and improving energy efficiency

Plant protection fabric: Shielding seedlings from adverse weather conditions

3. Packaging and Industrial Materials

Industrial demand for spunbond nonwoven continues to grow:

Composite packaging materials: Enhancing the strength and durability of packaging

Industrial wipes: Used for machinery cleaning and maintenance

Filtration media: Applied in air and liquid filtration systems

Acoustic and thermal insulation: Automotive and construction industry application

4. Protective Products (Non-Medical Grade)

Building on our experience in mask production, we provide:

Base materials for daily protective items: Used in ordinary protective face shields, isolation gowns, etc.

Hygienic protective materials: Suitable for general cleaning and protective scenarios

Industrial protective equipment: Providing basic protection for specific working environment

5. Other Innovative Applications

Crafts and DIY materials: Serving as base materials for creative projects

Stationery and office supplies: Used in folders, document holders, etc.

Automotive interiors: Acting as substrate for car ceilings, door panels, and other components

Footwear accessories: Applied as shoe lining and structural support

Customization Services: Meeting Your Unique Requirements

We recognize that each client's application needs are distinct, and thus we offer comprehensive customization services:

Material Characteristics Customization

Functional additives: Incorporating special additives like UV stabilizers, antimicrobial agents, etc.

Production Process Advantages

Our "Double S" certification ensures standardized production processes and consistent product quality. Through a rigorous quality control system, every step—from raw material procurement to finished product delivery—is meticulously monitored to ensure the products meet clients' technical specifications and performance requirements.

Guide to Selecting Suitable Spunbond Nonwoven

When choosing spunbond nonwoven, please consider the following factors:

End-use environment: Indoor/outdoor, contact with liquids/dry conditions, etc.

Physical performance requirements: Required tear strength, tensile strength, abrasion resistance

Regulations and standards: Industry-specific safety and performance requirements

Cost-effectiveness balance: The most economical choice that meets performance requirements

Industry Trends and Innovation Directions

The spunbond nonwoven industry is evolving in the following directions:

Sustainability: Increased use of recycled materials and bio-based polymers

Functional integration: Development of multifunctional composite materials to reduce processing steps

Smart manufacturing: Optimization of production processes and quality control through IoT technologies

Application expansion: Innovative applications in emerging fields such as new energy and environmental protection

Conclusion

As a professional spunbond nonwoven manufacturer, we are dedicated to helping clients achieve product value enhancement through innovative material solutions. Whether you require standard specifications or fully customized solutions, our technical team is always ready to provide expert advice and support.

Pro Tip: Before finalizing specifications, we recommend requesting samples for testing to ensure the material fully meets your processing requirements and end-use performance needs.

This article is provided by a professional spunbond nonwoven manufacturer. The content is based on general industry knowledge. For specific product selection, please consult our technical sales team for expert advice. Images in this article are generic industry illustrations used for explanatory purposes only.

Contact Us: Interested in learning more about our spunbond nonwoven products or discussing customization needs? Please reach out via the website contact form or email our sales team directly. We will respond to your inquiry within 24 hours.