In manufacturing and product design, the choice of material is one of the most critical decisions you'll make. It affects everything from product performance and durability to cost and market competitiveness. Among the various options available, polypropylene (PP) spunbond nonwoven fabric has emerged as a versatile and highly effective solution for countless applications.

As specialists in PP spunbond nonwoven manufacturing, we've witnessed firsthand how this material transforms products across industries. Here are five compelling advantages that make PP spunbond nonwoven an excellent choice for your next project.

Lower Production Costs:

PP resin is generally more affordable than polyester or other polymer alternatives

The spunbond production process is efficient, reducing manufacturing expenses

Lightweight nature means you use less material per square meter compared to heavier fabrics

Value Proposition:

Competitive pricing without compromising quality

Ideal for high-volume applications where cost control is essential

Excellent return on investment for disposable and semi-durable products

Applications Benefiting Most:

Disposable medical supplies

Packaging materials

Agricultural covers

Furniture and bedding components

Technical Advantages:

Resistant to most acids, alkalis, and organic solvents

Maintains integrity when exposed to chemicals that would degrade other materials

Non-reactive properties make it safe for sensitive applications

Industry Applications:

Medical: Sterilization wraps, surgical drapes

Industrial: Filtration systems, protective covers, chemical wipes

Agriculture: Pesticide-resistant ground covers

Cleaning: Industrial wipes for chemical spills

Testing Standards Met:

ISO 10993 (biological evaluation of medical devices)

ASTM standards for chemical resistance

Industry-specific compliance requirements

Performance Characteristics:

Low density (0.91 g/cm³) makes it one of the lightest commercially available fabrics

Excellent strength-to-weight ratio

Good abrasion resistance for its weight class

Benefits for Manufacturers:

Reduced shipping and handling costs

Easier integration into final products

Improved end-user comfort in wearable applications

Energy savings in transportation and logistics

Hydrophobic Nature:

Naturally repels water and liquids

Maintains dry surface characteristics

Prevents moisture absorption that could lead to bacterial growth

Customization Options:

Can be treated to become hydrophilic for specific applications

Available with various moisture management profiles

Treatment options include: permanent hydrophilic, temporary hydrophilic, and gradient absorption

Key Applications:

Hygiene Products: Diapers, feminine care, adult incontinence products

Medical: Wound dressings, surgical drapes

Apparel: Inner linings, protective layers

Packaging: Moisture-sensitive product protection

Recyclability:

PP is 100% recyclable (resin code #5)

Can be reprocessed into new nonwoven products or other plastic items

Growing infrastructure for PP recycling worldwide

Production Efficiency:

Lower energy consumption during manufacturing compared to many alternatives

Minimal waste in production process

Some production processes allow for closed-loop systems

Eco-Friendly Advantages:

Reduced Carbon Footprint: Lighter weight means lower transportation emissions

Alternative to Less Sustainable Materials: Can replace materials with higher environmental impact

Long-Term Potential: Biodegradable PP options are in development

Identify which advantages matter most for your application

Consider regulatory and compliance needs

Evaluate cost versus performance priorities

Weight: Choose appropriate GSM for your needs

Width: Consider production efficiency and material utilization

Treatments: Select surface modifications for enhanced performance

Look for suppliers with technical expertise

Request samples for testing

Discuss customization possibilities

Conduct real-world performance testing

Compare with alternative materials

Calculate total cost of ownership

At Henghua Nonwoven [Fuzhou Heng Hua New Material Co.,ltd.], we've specialized in PP spunbond nonwoven manufacturing for 22 years. Our commitment extends beyond simply supplying material—we partner with our clients to ensure they maximize all the advantages this remarkable material offers.

Our Capabilities Include:

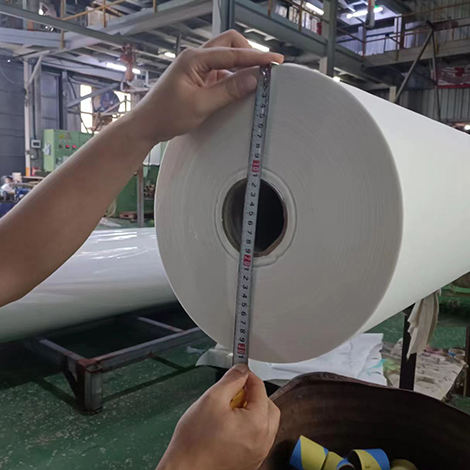

GSM range: 10-250 g/m²

Width options: 1.6~2.5 meters

Custom treatments: Hydrophobic, flame retardant, Anti-Static,Anti-Bacterial, Super Soft etc.

Color matching and custom formulations

Quick sampling and prototyping

Quality Assurance:

ISO 9001 certified manufacturing

Batch-to-batch consistency

Comprehensive testing and documentation

Traceability throughout production

Contact us at marketing@henghuanonwoven.com

E-mail : marketing@henghuanonwoven.com

Add : No.260 Liqi Road Hangcheng Street, Changle District, Fuzhou City, Fujian Province, China

leave a message

Scan to Wechat :

Scan to WhatsApp :