From Field to Shelf: The Versatile Journey of PP Spunbond Nonwoven Fabric

Jan 14, 2026

A truly remarkable material is one that solves problems in seemingly disparate fields with equal effectiveness. Polypropylene (PP) Spunbond Nonwoven Fabric is such a material, playing a silent yet crucial role from the very beginning of the supply chain in agriculture to the final point of sale on the retail shelf.

Part 1: Guardian of the Field – PP Spunbond in Protective Agriculture

Modern agriculture relies on technology to increase yield, protect crops, and conserve resources. PP Spunbond is an essential tool in this endeavor:

Weed Control & Soil Protection: Agricultural mulch fabric made from durable, UV-stabilized PP Spunbond suppresses weed growth without herbicides, conserves soil moisture, and regulates soil temperature. This leads to healthier plants, reduced water usage, and higher-quality yields.

Frost & Pest Protection: Used as a floating crop cover, this lightweight fabric acts as a protective blanket. It shields young plants from unexpected frost, prevents damage from birds and insects, and can even create a microclimate that accelerates growth.

Tree & Root Protection: In nurseries and landscaping, PP fabric is used for tree wrapping and as a barrier for root balls, protecting sensitive bark and roots during transport and transplanting.

The key here is durability and breathability. Unlike plastic films, spunbond allows air and water to pass through while providing robust physical protection, making it ideal for long-term agricultural applications.

Part 2: Protector of the Product – PP Spunbond in Industrial and Retail Packaging

The strength, flexibility, and cleanliness of PP Spunbond make it a superior choice for packaging solutions that demand more than just a container:

Durable Protective Packaging: It is widely used as a protective wrap for furniture, automotive parts, and delicate machinery. Its high tensile strength and puncture resistance prevent scratches and damage during storage and shipping far better than thin plastic or paper.

The Ideal Bag Material: From reusable totes to high-end gift bags and soil bags for gardening, PP Spunbond offers a premium, cloth-like feel with excellent printability for branding. It is more durable than paper and more sustainable than single-use plastic bags.

Composite Material Backbone: PP Spunbond often serves as the strong, stable scrim or backing layer in laminated packaging materials, adding tear resistance and structure to other functional layers.

The Common Thread: Performance Meets Practicality

Whether in the field or the warehouse, PP Spunbond succeeds because of its consistent core properties: excellent strength-to-weight ratio, moisture resistance, breathability (where needed), and cost-effectiveness. It’s a versatile workhorse that provides reliable, high-value performance.

Bridging Industries with One Reliable Material

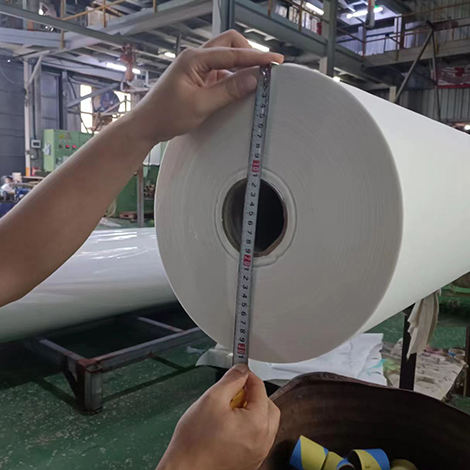

At Henghua Nonwoven, we understand the unique needs of both agricultural and packaging industries. We produce tailored PP Spunbond fabrics—with specific weights, UV treatments, colors, and finishes—to excel in each environment.

From safeguarding the season’s harvest to ensuring your products arrive in perfect condition, our fabrics are engineered for the journey.

Contact us discuss your specific application challenge.