Spunbond Nonwoven: The Engine Behind Modern Materials

Dec 25, 2025

Spunbond Nonwoven: The Engine Behind Modern Materials

At Henghua Nonwoven, we are at the heart of innovation, crafting the essential fabrics that shape everyday life. As a leading spunbond nonwoven manufacturer, we don’t just produce materials; we engineer solutions. Today, we’re diving into the world of spunbond nonwoven fabric – a versatile, durable, and indispensable material that is often unseen but always felt.

What Exactly is Spunbond Nonwoven?

Unlike traditional woven or knitted textiles made from yarn, nonwoven fabrics are made directly from fibers bonded together. The spunbond process is a specific, continuous method where we extrude molten polymer (like polypropylene, polyester, or biopolymers) through fine spinnerets to form continuous filaments. These filaments are then laid down randomly onto a moving conveyor belt and bonded together – typically using thermal, mechanical, or chemical methods – to create a strong, uniform fabric.

The result? A material with a unique set of properties: high strength-to-weight ratio, excellent breathability, liquid repellency, and consistent quality. It’s cost-effective, customizable, and incredibly reliable.

The Spunbond Process: Our Precision Engineering

As a dedicated manufacturer, our expertise lies in mastering this continuous process. It can be broken down into four key stages:

1. Extrusion: Polymer granules are melted and forced through spinnerets, creating a curtain of continuous filaments.

2. Drawing & Attenuation: High-speed air streams stretch and thin the filaments, aligning their molecules for enhanced strength.

3. Web Formation: The drawn filaments are randomly dispersed onto a moving belt, forming a uniform web.

4. Bonding: The web is consolidated, most commonly through thermal bonding (calendaring with heated rollers), which creates a smooth, strong fabric.

This controlled process allows us to tailor every aspect of the fabric to your needs: weight (gsm), width, color, strength, softness, and permeability.

Where is Spunbond Nonwoven Used? (Our Solutions in Action)

The applications are vast and growing, a testament to the material’s adaptability. At Henghua Nonwoven, we provide high-quality spunbond for critical sectors:

Hygiene & Healthcare: The backbone of disposable hygiene products. Our fabrics are trusted for diapers, feminine care products, adult incontinence products, and medical gowns/drapes due to their softness, strength, and fluid management.

Agriculture: We empower modern farming with crop covers, weed control fabrics, and seedling bags that protect plants, promote growth, and conserve water.

Geotextiles & Construction: Providing strength and stability, our fabrics are used for soil stabilization, erosion control, drainage systems, and roofing membranes.

Filtration: From HVAC filters to liquid filtration, our consistent pore structure and durability make for efficient and long-lasting filter media.

Packaging & Furniture: Lightweight yet tough, spunbond is ideal for shopping bags, protective covers, and furniture backing.

Why Partner with Henghua Nonwoven?

Choosing the right manufacturer is crucial. Here’s what sets us apart:

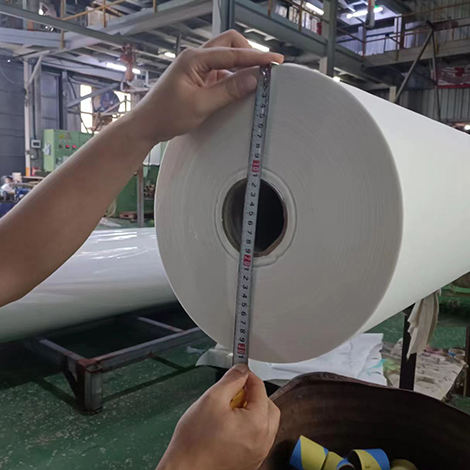

Vertical Integration & Quality Control: We control the process from polymer to finished roll, ensuring unmatched consistency and quality at every step.

Innovation & Customization: Our R&D team works closely with clients to develop custom fabrics for specific challenges. Need a unique color, additive (like fire retardants or UV stabilizers), or special finish? We can create it.

Commitment to Sustainability: We are actively developing solutions using recycled polymers and bio-based materials, and our efficient production process minimizes waste. We provide materials that help our clients meet their environmental goals.

Global Reach, Local Expertise: With a robust production capacity and a reliable supply chain, we serve clients worldwide, offering timely delivery and expert technical support.

Driven by Your Needs: We are more than a supplier; we are a partner. We invest in understanding your application to deliver the optimal material that enhances your product’s performance and value.

The Future is Woven with Innovation

The demand for smarter, more sustainable, and higher-performance materials is accelerating. At Henghua Nonwoven, we are committed to leading this change. We are continuously refining our processes, exploring new raw materials, and developing next-generation spunbond fabrics that are stronger, softer, and greener.

Are you looking for a reliable, innovative partner for your spunbond nonwoven needs?

Explore the possibilities with Henghua Nonwoven. Let's discuss how our engineered fabrics can become the foundation for your next successful product.