Beyond the Fabric: How Fuzhou Henghua New Material is Redefining Nonwoven Excellence

Dec 12, 2025

At Fuzhou Henghua New Material Co., Ltd., we often say we don't just make nonwoven fabric; we engineer possibilities. In an industry where "spunbond" might sound like a commodity, we see a canvas for innovation, a testament to precision, and a cornerstone for global progress. For our partners worldwide, choosing a supplier goes beyond price per square meter—it's about trust, consistency, and a shared vision for a better-performing product.

So, what truly differentiates a roll of our spunbond nonwoven from the rest? The answer is woven into every fiber of our process.

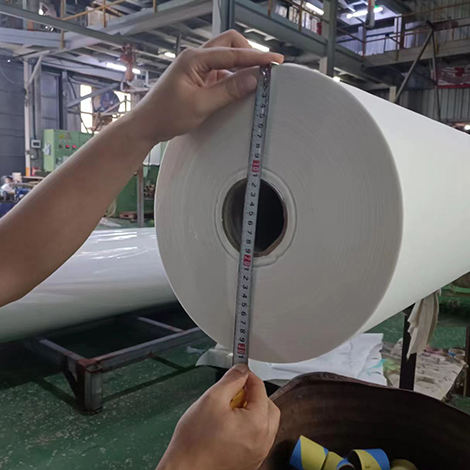

The Precision Engineering Behind the Roll

While the spunbond process is well-known, the devil—and the divinity—is in the details. Our commitment starts with molecular-grade scrutiny of our polypropylene raw materials. Consistent polymer quality is non-negotiable; it’s the first step in ensuring superior tensile strength, uniformity, and excellent hydrostatic pressure resistance in our final product.

In our state-of-the-art facility, the magic happens through continuous filament technology. We precisely control every variable: from the polymer extrusion temperature and filament drawing to the lay-down and thermal bonding process. This results in a fabric with an optimal balance of softness and strength, exceptional dimensional stability, and a uniformity that sets a new benchmark. Whether it's for hygiene, medical, agricultural, or protective applications, our fabric performs with unwavering reliability.

Sustainability: A Thread Running Through Everything We Do

Modern manufacturing carries a responsibility. Our commitment at Fuzhou Henghua is not only to our clients but also to the planet. Our production process is designed for efficiency, minimizing waste and energy consumption. Furthermore, as a 100% polypropylene-based material, our spunbond nonwoven is fully recyclable, supporting the circular economy goals of our global partners. We offer solutions that help brands meet their sustainability targets without compromising on performance.

More Than a Supplier: Your Strategic Partner in Innovation

We understand that your challenges are unique. A diaper manufacturer needs exceptional fluid management and breathability. A furniture producer requires specific drape and tear resistance. A agricultural partner looks for optimal light transmission and durability. This is where we transition from a vendor to a partner.

Our technical team thrives on collaboration. We don't just sell standard grades; we delve into the specifics of your application. Can we adjust the basis weight for more cost-efficiency? Optimize the UV resistance for longer crop cycles? Enhance the fabric's hand feel for a premium product? At Fuzhou Henghua, we have the R&D capability and flexible production lines to co-develop tailored solutions. Your success is the true measure of our fabric's quality.

The Fuzhou Henghua Promise: Global Standards, Delivered

In today's interconnected world, consistency is key. Whether you're ordering a container to Hamburg, Houston, or Ho Chi Minh City, you can expect the exact same standard of excellence. Our rigorous Quality Management System ensures every roll that leaves our facility meets international standards and your specific specifications.

We are Fuzhou Henghua New Material Co., Ltd.: Engineers of nonwoven fabric, partners in progress, and a reliable link in your supply chain. We invite you to look beyond the fabric and see the innovation, dedication, and partnership we weave into every square meter.

Let's build the future, layer by precise layer.

Connect with us to discuss how our engineered spunbond solutions can elevate your next project.