The Quiet Revolution: PP Spunbond Nonwoven

Feb 06, 2026

Look around you. That reusable shopping bag, the protective layer in your face mask, the barrier fabric in your favorite gardening sheet, even the cozy lining in your car’s trunk. What do they have in common? There’s a high chance they are made from a remarkable material you probably encounter daily without even knowing its name: PP Spunbond Nonwoven.

it's the invisible workhorse of industries from healthcare to home improvement. But what exactly is it, and why is it so ubiquitous? Let’s unravel the story of this versatile fabric.

What is PP Spunbond Nonwoven?

The name breaks down into its core components:

PP: Stands for Polypropylene, a type of thermoplastic polymer. it's known for being lightweight, chemically resistant, and incredibly durable.

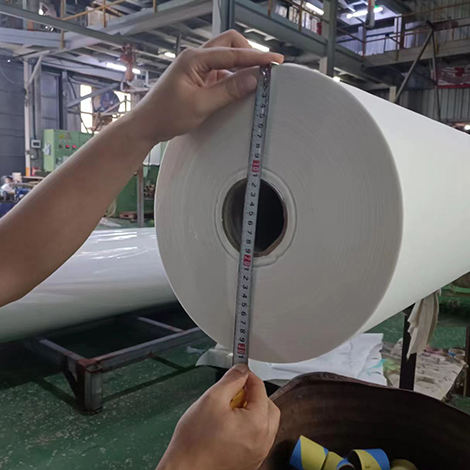

Spunbond: This refers to the manufacturing process. Molten polypropylene is extruded through fine spinnerets to create continuous filaments. These filaments are then laid down onto a moving conveyor belt in a random web formation.

Nonwoven: Unlike traditional woven or knitted fabrics made from yarns, nonwovens are sheets of fibers bonded together by thermal, mechanical, or chemical means. In the case of spunbond, the web of filaments is thermally bonded (using heated rollers), fusing the fibers at their crossover points.

The result? A fabric that is strong, consistent, and engineered for specific functions rather than aesthetics.

Key Properties & Advantages: Why Its So Popular

PP Spunbond Nonwoven isn’t just common by accident. Its properties make it a superstar for countless applications:

Lightweight & Strong: It offers an excellent strength-to-weight ratio, providing durability without bulk.

Breathable: The porous structure allows air and moisture vapor to pass through, making it ideal for hygiene and medical products.

Water-Resistant: Polypropylene is inherently hydrophobic (repels water). While not waterproof, it provides a excellent barrier against fluids and moisture.

Chemically Inert: It resists mildew, bacteria, and many acids and alkalis, ensuring longevity and hygiene.

Cost-Effective: The spunbond process is fast, continuous, and efficient, producing high volumes of fabric at a relatively low cost.

Eco-Friendly Potential: PP is recyclable. Many spunbond products are designed for single-use, reducing cross-contamination risks (critical in medical settings), but the material itself can be repurposed. Biodegradable and bio-based PP options are also emerging.

Where Do You Find It? Applications Galore

This is where the magic happens. PP Spunbond's versatility shines across sectors:

Hygiene & Healthcare: The backbone of disposable medical gowns, surgical drapes, face masks, shoe covers, and sterilization wraps. Also, the top sheet and back sheet of baby diapers and feminine hygiene products.

Agriculture: Used as crop covers (frost protection, weed control), plant protection bags, and landscaping fabric to suppress weeds while allowing water through.

Geotextiles: In civil engineering, it's used for soil stabilization, drainage, erosion control, and road construction due to its filtration and separation capabilities.

Packaging: Durable shopping bags, wine bottle wraps, and protective packaging for furniture and textiles.

Home Furnishings: As bed mattress protectors, pillow covers, furniture backings, and carpet underlays.

Apparel: As interlinings, disposable clothing for cleanrooms or painting, and even components in footwear.

The Future: Innovation and Sustainability

The future of PP Spunbond is bright and focused on two key areas:

Enhanced Functionality: Developments include hydrophilic (water-attracting) treatments for specific uses, antimicrobial coatings, and laminated composites with other nonwovens (like SMS – Spunbond-Meltblown-Spunbond) for superior barrier protection.

Circular Economy: The industry is heavily investing in mono-material designs for easier recycling, using recycled polypropylene (RPP) as raw material, and advancing chemical recycling technologies to close the loop.

Conclusion

PP Spunbond Nonwoven is the quiet, reliable foundation of modern convenience, safety, and efficiency. it's a testament to how material science and smart engineering can create a simple-looking fabric with profound impacts. The next time you reach for a disposable mask, lay down a gardening sheet, or carry a sturdy tote bag, you’ll appreciate the sophisticated web of technology right at your fingertips.

It's more than just fabric; it's a seamlessly engineered solution woven into the fabric of everyday life.

Looking for a reliable spunbond PP solution??

Contact our team today for a free consultation and sample testing. Let us help you make an informed choice that enhances your product's performance and value.

Email: marketing@henghuanonwoven.com

Website: www.henghuanonwoven.com