The Essential Role of Spunbond Nonwoven Fabric in Modern Supply Chains & Sustainability

Jan 30, 2026

Introduction: The Unseen Backbone of Modern Products

In today's interconnected world, the journey of a product from raw materials to consumer hands relies on often-overlooked components that ensure protection, preservation, and presentation. Among these unsung heroes is spunbond polypropylene nonwoven fabric—a versatile material that has quietly revolutionized packaging, protection, and numerous industrial applications. As global supply chains face increasing pressures for efficiency and sustainability, understanding this material's role becomes crucial for businesses seeking competitive advantages. At Fuzhou Henghua New Material Co., Ltd., we've spent years perfecting the art of manufacturing adaptable, high-performance spunbond nonwoven that meets the evolving demands of diverse industries.

The Material Science: Why Spunbond Polypropylene Stands Apart

Spunbond technology represents a remarkable fusion of polymer science and textile engineering. Through extrusion of polypropylene pellets into continuous filaments that are laid into uniform webs and thermally bonded, manufacturers create fabrics with exceptional properties. Unlike traditional woven materials that can fray or unravel, spunbond nonwoven offers consistent strength in all directions thanks to its random filament orientation. This manufacturing process allows for precise control over weight, thickness, and porosity without the weaknesses of directional grain.

The choice of polypropylene as the base polymer is equally significant. This material provides natural resistance to moisture, chemicals, and mildew—qualities essential for products that must withstand challenging environments. Additionally, polypropylene's thermoplastic nature makes it ideal for further processing and customization through lamination, coating, or ultrasonic welding. These fundamental characteristics explain why spunbond nonwoven has displaced traditional materials in countless applications across industries.

Critical Applications Transforming Industries

Reinventing Protective Packaging

The fragility of modern electronics, precision instruments, and delicate components demands intelligent protective solutions. Spunbond nonwoven has emerged as a superior alternative to foam, bubble wrap, and paper-based materials in this domain. Its exceptional cushioning properties combined with anti-static capabilities make it ideal for separating and protecting electronic components during shipping and storage. Unlike foam that can degrade or bubble wrap that can puncture, spunbond fabric maintains its protective integrity through compression and vibration. Major electronics manufacturers increasingly specify this material for its reliability, cleanliness, and consistent performance.

For furniture and appliance manufacturers, heavier-weight spunbond nonwoven (typically 80-150gsm) serves as an effective anti-scratch surface protector. Its flexibility allows it to conform to curved surfaces while its durability withstands handling and transit. Unlike plastic films that can trap moisture and cause condensation damage, spunbond's microporous structure allows for breathable protection—a crucial advantage for products susceptible to humidity damage.

Revolutionizing Agricultural Productivity

Modern agriculture faces the dual challenge of increasing yields while managing environmental impacts. Spunbond nonwoven has become an indispensable tool in this balancing act. As crop covers and frost protection, lighter-weight fabrics (17-30gsm) create microclimates that extend growing seasons, conserve water by reducing evaporation, and minimize pest damage without chemical interventions. These fabrics provide the unique combination of light transmission for photosynthesis while regulating temperature and moisture—an engineering feat traditional materials cannot match.

For more demanding agricultural applications, heavier nonwoven fabrics serve as weed control barriers in orchards and vineyards, suppressing unwanted growth while allowing water penetration to reach crop roots. In hydroponic systems, specialized spunbond materials provide optimal root support and moisture distribution. The material's UV-stabilized variants ensure season-long durability under harsh sunlight, representing a sustainable alternative to plastic mulches that fragment and contaminate soil.

Advancing Medical and Hygiene Standards

The healthcare sector demands materials that meet uncompromising standards of purity, consistency, and safety. Spunbond nonwoven fulfills these requirements through manufacturing processes that maintain sterile environments and material uniformity. In single-use medical applications such as surgical drapes, gowns, and instrument wraps, the fabric's barrier properties prevent microbial transmission while maintaining breathability for comfort. Unlike reusable textiles that may harbor pathogens despite laundering, single-use spunbond products eliminate cross-contamination risks—a critical consideration in infection control.

The hygiene product industry has been transformed by the advent of ultra-lightweight spunbond fabrics (10-25gsm) that provide softness, strength, and fluid management in carefully engineered layered structures. These fabrics offer superior comfort and performance compared to traditional materials, with the added advantage of being thinner and more environmentally efficient in production and transportation. Our capability to produce fabrics as light as 10gsm with consistent quality enables manufacturers to create next-generation products that balance performance with material efficiency.

Sustainability Advantages: The Eco-Conscious Choice

In an era of heightened environmental awareness, spunbond nonwoven presents compelling sustainability advantages. Unlike many alternative materials, polypropylene is fully recyclable and increasingly incorporated into circular economy models. Our production process generates minimal waste, with edge trimmings and off-spec materials routinely recycled back into production streams—an approach that minimizes raw material consumption.

The material's lightweight nature translates directly to reduced transportation emissions. When compared to traditional textiles or paper alternatives of equivalent strength, spunbond nonwoven typically requires less material mass to achieve the same performance, creating a cascade of efficiency benefits throughout the supply chain. Furthermore, the durability of spunbond products often enables multiple reuses in industrial applications before recycling—extending the material's service life and reducing overall consumption.

For disposable applications where reuse isn't feasible, spunbond polypropylene offers advantages in end-of-life scenarios. Unlike materials that fragment into microplastics, properly managed polypropylene maintains structural integrity for efficient collection and recycling. Additionally, when incineration with energy recovery is the disposal method, polypropylene's high calorific value makes it an efficient fuel source that produces primarily carbon dioxide and water vapor when completely combusted.

Customization Capabilities: Tailoring Solutions to Specific Needs

At Fuzhou Henghua New Material Co., Ltd., we recognize that superior materials must adapt to specific applications rather than forcing applications to adapt to limited material options. Our comprehensive customization capabilities ensure clients receive precisely optimized solutions:

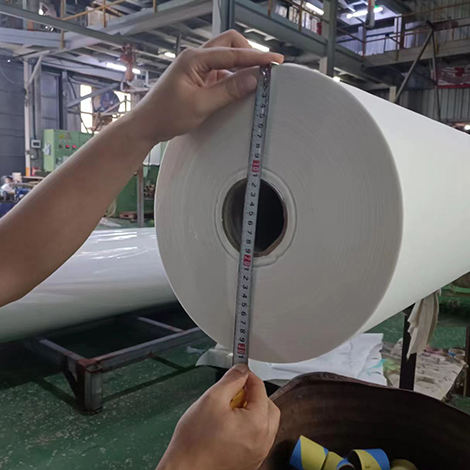

Weight Precision: With a production range from 10 to 250gsm, we can engineer fabrics with the exact balance of strength, flexibility, and substance required. This spectrum encompasses everything from whisper-thin hygiene layers to rugged geotextiles capable of withstanding extreme mechanical stress.

Dimensional Flexibility: Our width customization from 15 to 255cm allows clients to minimize waste by matching fabric dimensions to their production requirements. Whether creating narrow tapes or wide-format coverings, we optimize dimensions for efficiency.

Specialized Treatments: Beyond standard offerings, we apply functional treatments including UV stabilization for outdoor durability, hydrophilic treatments for fluid absorption, flame retardancy for safety applications, and anti-static properties for electronics protection.

Color Integration: Our color matching capabilities extend beyond aesthetics to functional applications where color-coding different product lines or grades enhances operational efficiency and minimizes errors in industrial settings.

Partnering for Success: The Fuzhou Henghua Advantage

Navigating material selection requires more than product catalogs—it demands technical partnership. Our approach begins with understanding your application challenges, performance requirements, and production parameters. Through collaborative analysis, we identify the optimal specification balance, then produce pilot quantities for your evaluation before scaling to full production.

Our vertically integrated manufacturing ensures quality control at every stage, from polymer selection to final winding. This control, combined with ISO-certified processes, delivers the consistency that modern production lines require. As your production volumes or product specifications evolve, our flexible approach adapts to maintain seamless supply chain integration.

The proof of material suitability lies in tangible experience. We facilitate this through comprehensive sample programs that allow you to test fabrics in your actual application environment before committing to production volumes. This risk-mitigation approach has established trust with clients across diverse industries and geographies.

Conclusion: Material Intelligence for Competitive Advantage

In the increasingly complex landscape of product development and supply chain management, material intelligence delivers distinct competitive advantages. Spunbond nonwoven fabric represents more than a commodity—it's an enabling technology that solves multidimensional challenges of protection, presentation, preservation, and sustainability.

As you evaluate materials for current or upcoming projects, consider the full spectrum of benefits that custom-engineered spunbond nonwoven delivers: application-specific performance, supply chain efficiency, environmental responsibility, and total cost optimization. These advantages explain why forward-thinking companies across industries are transitioning from generic materials to purpose-engineered solutions.

Discover how our tailored spunbond nonwoven fabrics can enhance your products and processes. Contact Fuzhou Henghua New Material Co., Ltd. today to begin a technical consultation. Share your application requirements, and our specialists will recommend optimized specifications and provide material samples for your evaluation. Let's collaborate to materialize your next innovation.

Call to Action:Visit our website's technical resources section or contact our engineering team directly to request our Application Selection Guide—a comprehensive resource detailing specifications for various industrial uses of spunbond nonwoven fabric. For immediate project consultation, submit your material requirements through our online specification form to receive customized recommendations within 48 hours.