The Complete Guide to Spunbond Nonwoven Fabric: Manufacturing, Types, and Applications

Dec 26, 2025

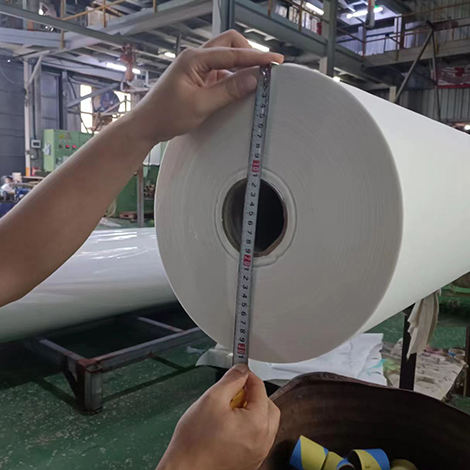

How Spunbond Fabric is Made: The Engineering Behind the Material

Spunbond nonwoven fabric is manufactured through a highly controlled, continuous process known as spunbonding. It begins with thermoplastic polymer granules—most commonly polypropylene—which are melted and extruded through fine spinnerets to form continuous filaments. These filaments are then stretched, cooled, and laid onto a moving conveyor belt in a randomized web formation. Finally, the web is bonded using thermal, chemical, or mechanical methods to create a cohesive, uniform fabric. This efficient production method allows for high-volume manufacturing while maintaining consistent quality and performance.

Spunbond vs. Spunlace: Understanding Nonwoven Variants

While both are types of nonwoven fabrics, spunbond and spunlace differ significantly in their production and properties:

Spunbond: As described above, uses thermal or chemical bonding of continuous filaments. It tends to be stronger, lighter, and more cost-effective for large-scale applications like geotextiles, packaging, and disposable medical products.

Spunlace: Also known as hydroentangled fabric, spunlace uses high-pressure water jets to entangle fibers, creating a soft, cloth-like texture. It is highly absorbent, lint-free, and gentle, making it ideal for wipes, hygiene products, and premium cosmetic applications.

Choosing between them depends on whether you prioritize strength and economy (spunbond) or softness and absorbency (spunlace).

Key Properties and Performance of Spunbond Nonwovens

Water Resistance and Breathability

Spunbond is not inherently 100% waterproof—completely waterproof fabrics typically involve coated or laminated materials like PU-coated polyester or PVC. However, spunbond’s micro-porous structure allows air and moisture vapor to pass through while resisting liquid water penetration under low pressure. This makes it excellent for breathable protective covers, agricultural fabric, and disposable medical gowns.

In geotextile applications, non-woven fabrics like spunbond do allow water to pass through—this is actually one of their key advantages. They provide excellent filtration and drainage by permitting water flow while preventing soil migration.

Comfort and Seasonal Suitability

Spunbond fabric is lightweight, breathable, and often used in disposable clothing and covers. While not typically designed for fashion apparel, its structure can offer decent airflow, making it suitable for summer-use products like disposable sun hats, light covers, or agricultural shade cloths. For extended wear, however, traditional woven natural fabrics may offer better comfort.

Durability and Lifespan

The lifespan of nonwoven fabric varies widely based on material, bonding method, and exposure conditions. Spunbond polypropylene geotextiles, for example, can last 5–20 years underground depending on UV exposure, chemical environment, and mechanical stress. In disposable applications, lifespan is intentionally short-term—from single use to several months.

Advantages of Bonded Fabrics (Nonwovens)

Nonwovens like spunbond offer unique benefits that woven fabrics cannot match:

Cost-Efficiency: Faster production with fewer steps reduces costs.

Customizable Properties: Weight, thickness, strength, and permeability can be engineered.

Consistency: Uniform structure without grain or bias.

Disposability & Hygiene: Ideal for medical, sanitary, and filtration products.

Versatility: Used across industries—from agriculture to healthcare to construction.

How to Identify Non-Woven Fabric

You can recognize non-woven fabric by:

Visual Inspection: No visible weaving or knitting pattern; fibers appear randomly arranged.

Tactile Feel: Often feels paper-like or fibrous, and may tear more easily than woven cloth.

Edge Behavior: Nonwovens tend to fray minimally, and edges can sometimes be pulled apart like felt.

Water Test: Many nonwovens will allow water to pass through quickly (unless treated).

Maintenance and Sustainability

Cleaning Non-Woven Materials

Most spunbond nonwovens are designed for single use and are not washable. However, in reusable applications like certain geotextiles or shopping bags, gentle surface cleaning with a damp cloth is possible. Avoid machine washing, as this can break down the fiber bonds.

Environmental Perspective

The question “Is nonwoven material good or bad?” depends on use and lifecycle management. While spunbond is plastic-based and slow to degrade, its lightweight nature and efficiency in specialized applications (like reducing infection spread in hospitals) offer functional benefits. The industry is moving toward recycled materials and biodegradable polymers to improve sustainability.

The Three Main Types of Nonwoven Fabric

Spunbond – Filament-based, bonded thermally/chemically. Strong, lightweight.

Spunlace – Hydroentangled, soft, absorbent. Used in wipes and hygiene.

Meltblown – Ultra-fine fibers, excellent filtration. Common in masks and filters.

Many fabrics combine these, such as SMS (Spunbond-Meltblown-Spunbond) used in medical protective wear.

Why Partner with HengHua New Material?

At HengHua New Material Co., Ltd., we don’t just manufacture spunbond nonwoven fabric—we engineer solutions. With advanced technology, strict quality control, and a commitment to sustainable innovation, we provide fabrics that meet precise performance requirements for protection, agriculture, hygiene, and industry.

Whether you need permeable geotextiles, breathable protective layers, or reliable disposable materials, our technical team can help you select the right nonwoven type, weight, and treatment for your project.

Contact us today to request samples or discuss your next project with a trusted spunbond specialist.